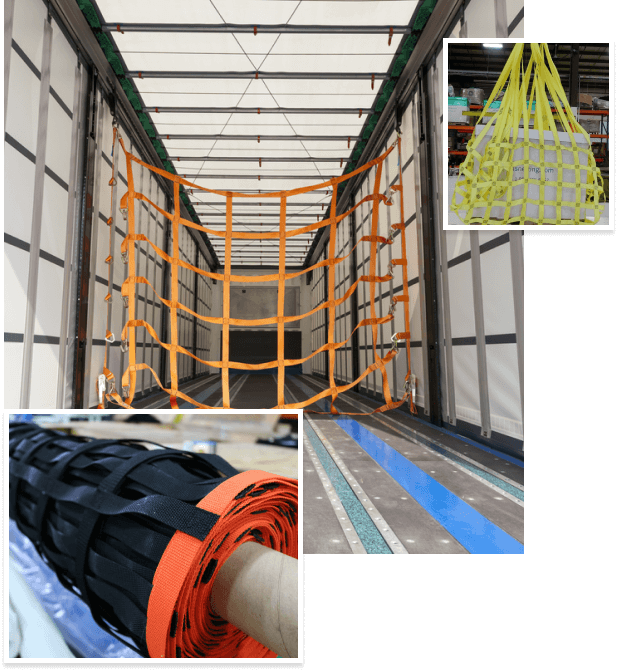

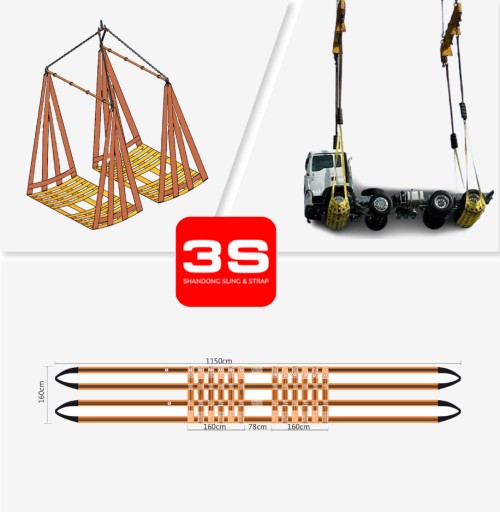

Webbing straps are very crucial in various industries and everyday lives. Webbing strength is essential, whether it is used to secure cargo or create safety harnesses. Professionals and consumers continue to debate the merits of polyester versus nylon webbing. Being aware of the differences enables individuals to make more informed decisions based on their specific needs. What is Webbing Material? Webbing is a tough strip of fabric woven from synthetic fibers. These strips vary in thickness and width. The fibers are woven tightly by manufacturers, creating maximum strength and durability. Polyester and nylon webbing are used for quite different purposes. All the materials possess distinct characteristics, making them suitable for specific applications. The decision regarding them will depend on the environmental conditions and special requirements. Comparison of Strengths of Materials. Raw Breaking Strength Lab experiments revealed that Nylon webbing had a slightly higher breaking strength. It has the capacity to experience this stretch breakage, which is also effective in absorbing shock loads. The elasticity eliminates unexpected breakdowns during tension. However, polyester webbing compares very well with nylon in terms of raw strength. The breaking strength difference usually differs between 10 and 15 percent. In the majority of working cases, such a difference is never essential. Working Load Limits Working load limits indicate to users the amount of weight webbing that can be used safely. Polyester is used as a webbing material that has uniform strength grades under varying conditions. This predictability and consistency make the use of strength easier and more foreseeable. Stable polyester webbing performance provides it with superiority in use in the work industry. Polyester allows users to rely on it to perform the same task repeatedly. Such uniformity minimizes safety hazards in emergencies. The benefits of Polyester Webbing. Superior UV Resistance Polyester has a better response to sunlight when compared to nylon. Nylon fibers are broken down over time by UV rays, resulting in less strength. Polyester does not deteriorate under the sun and retains its strength over time in the outdoors. Polyester has high sun-resistance and is used in outdoor applications. Polyester is used in tie-down straps, outdoor equipment, and awnings. The material remains so firm even after months or years in direct sunlight. Minimal Water Absorption Webbing materials are enormously problematic due to water uptake. Nylon captures the moisture with ease, and under wet environments, the material can lose up to 15 percent of its capacity. It also makes the material heavier, in addition to increasing the drying time. Polyester webbing does not take up much water, and it remains strong even when wet. It is the property that makes polyester suitable for marine applications and environments with high moisture content. The webbing will retain the working weight of the load-bearing even when thoroughly wet. Better Chemical Resistance The chemicals and acids destroy the nylon webbing very fast. Nylon fibers can be permanently weakened even when they are subjected to mild acid exposure. It is a weakness that restricts the use of nylon in industrial environments. Polyester is a type of webbing that is resistant to most common chemicals and acids. Polyester is preferred in industrial premises because it is used to handle chemical containers and equipment. The material is not affected when subjected to exposure that would ruin nylon webbing. Excellent Dimensional Stability. Dimensional stability refers to the property of webbing retaining its shape and length when subjected to a load. Nylon has significant elasticity with weight application occasionally reaching up to 30 percent. Its extension addresses an issue with applications that require precise measurements. Polyester webbing is not stretchy but has very low values, usually less than 3 percent at working loads. Polyester is ideal for use in objects that are heavy due to its stability, ensuring that they are lifted and positioned accurately. Users can rely on polyester to maintain the proper tension without requiring frequent adjustments. Long-term Durability Polyester webbing is longer-lasting in real-life situations. The UV resistance, coupled with chemical resistance and water resistance, enhances the lifespan of the services. Polyester straps are highly durable, with many remaining in operation for over 10 years. The implication of increased webbing lifespan is low replacement costs. Firms will end up spending less money replacing it with polyester webbing that takes up relatively lower maintenance. The initial investment will be compensated by innumerable years of reliable service. Comprehending the Nylon Webbing. When Nylon Works Better Specifically, Nylon webbing has its merits. Nylon can be used in locations where there is no issue of exposure to UV. To absorb a shock, nylon is more desirable since it has the property of higher elasticity. Fall arrests and rock climbing utilize it to some extent due to its stretching nature, which is achieved by using nylon. The cushions are made of a material that offers better protection against sudden impacts compared to polyester. In some cases, injuries can be prevented by this shock absorption. Limitations of Nylon The problem with moisture absorption poses continuous problems with nylon. Wet nylon becomes weak and unstable when used in essential jobs. Storage indoors helps, but it does not remove moisture-related issues. Nylon webbing used in an outdoor setting will require regular changes due to UV degradation. The weakness develops over a long period and may not be immediately noticeable. The hidden harm poses safety hazards, which are avoided by polyester webbing. Making the Right Choice Evaluating Your Needs Think about areas in which webbing shall be the most prevalent. Polyester webbing is the preferred choice for outdoor applications due to its sturdiness. The two materials can be used indoors, depending on the desired application, but polyester may still be beneficial. Consider water contact, chemicals, or sunlight. Polyester will react to all these situations better than nylon. The difference in raw strength is hardly significant compared to environmental resistance. Cost Considerations Polyester webbing is often slightly more expensive initially than nylon. Nevertheless, polyester has a longer service life and is generally more cost-effective. A reduced number of replacements results in reduced overall costs. Price should never be the criterion when it comes to safety equipment that is to be used. The improved performance of the polyester webbing can offset the high cost. Reliable primary equipment prevents accidents and protects valuable cargo. Conclusion Polyester webbing is the preferred option in most cases. Polyester is the intelligent choice due to its strength, durability, and ability to withstand various environmental factors. Although nylon has a marginally better raw strength, polyester works better where it is needed most.